Open Standard Modules™ - OSM

Open Standard Modules™, OSM for short, are extremely compact, BGA (Ball Grid Array) mini-modules that can be machine assembled and soldered. They were developed according to the manufacturer-independent standard of SGET, which is supported by leading embedded manufacturers. When designing the new standard, great emphasis was placed on flexibility and future viability. The design supports all common architectures such as ARM, x86, or MCU32. The modules feature hardware and software interfaces pre-defined by SGET and are basically interchangeable. Furthermore, all essential board components such as CPU, working, and flash memory are already integrated on the modules. Due to their affordable price, compact size, high energy efficiency, and robustness, OSM modules are perfectly suited for applications in medical technology, automation, transportation, and charging infrastructure.

The advantages of our OSM at a glance:

- Solder-on modules (BGA)

- Ultra flat and compact

- Interchangeability across generations

- Standardized interfaces

- Designed for ARM, x86 or MCU32 architecture

- Future-proof

- Manufacturer-independent

- Long-term availability

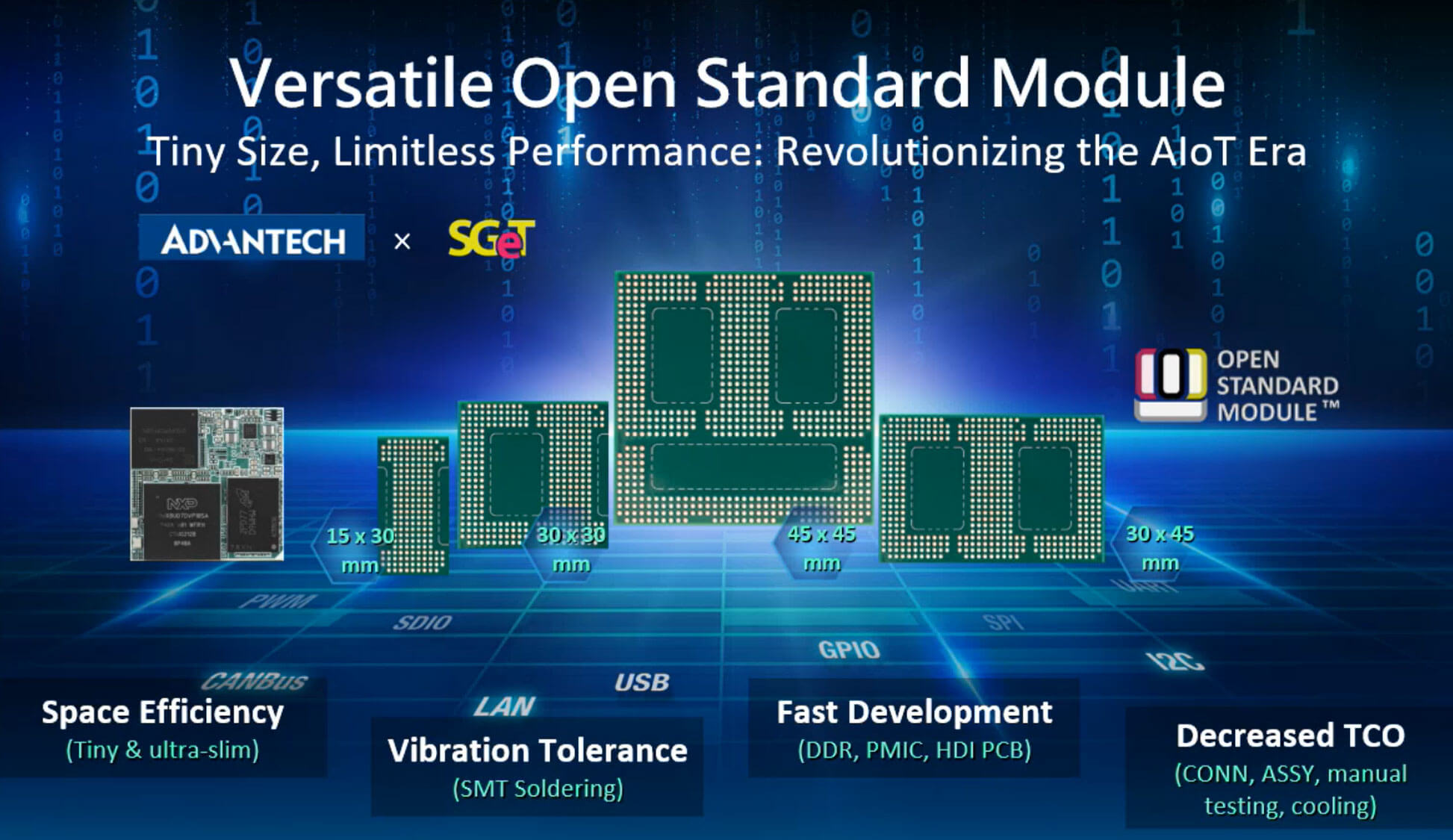

The OSM standard supports BGA soldering modules in the following sizes and with different numbers of ball grid arrays:

| Size 0 (Zero): | 30 mm x 15 mm with 188 BGA-pins |

| Size S (Small): | 30 mm x 30 mm with 332 BGA-pins |

| Size M (Medium): | 30 mm x 45 mm with 476 BGA-pins |

| Size L (Large): | 45 mm x 45 mm with 662 BGA-pins |

The new standard for the extremely compact solder-on modules is intended to supplement the existing pluggable standards such as SMARC, Qseven, COM Express™ Basic, Compact Mini or the COM-HPC Server / Client Standard and opens up new possibilities for miniaturization.

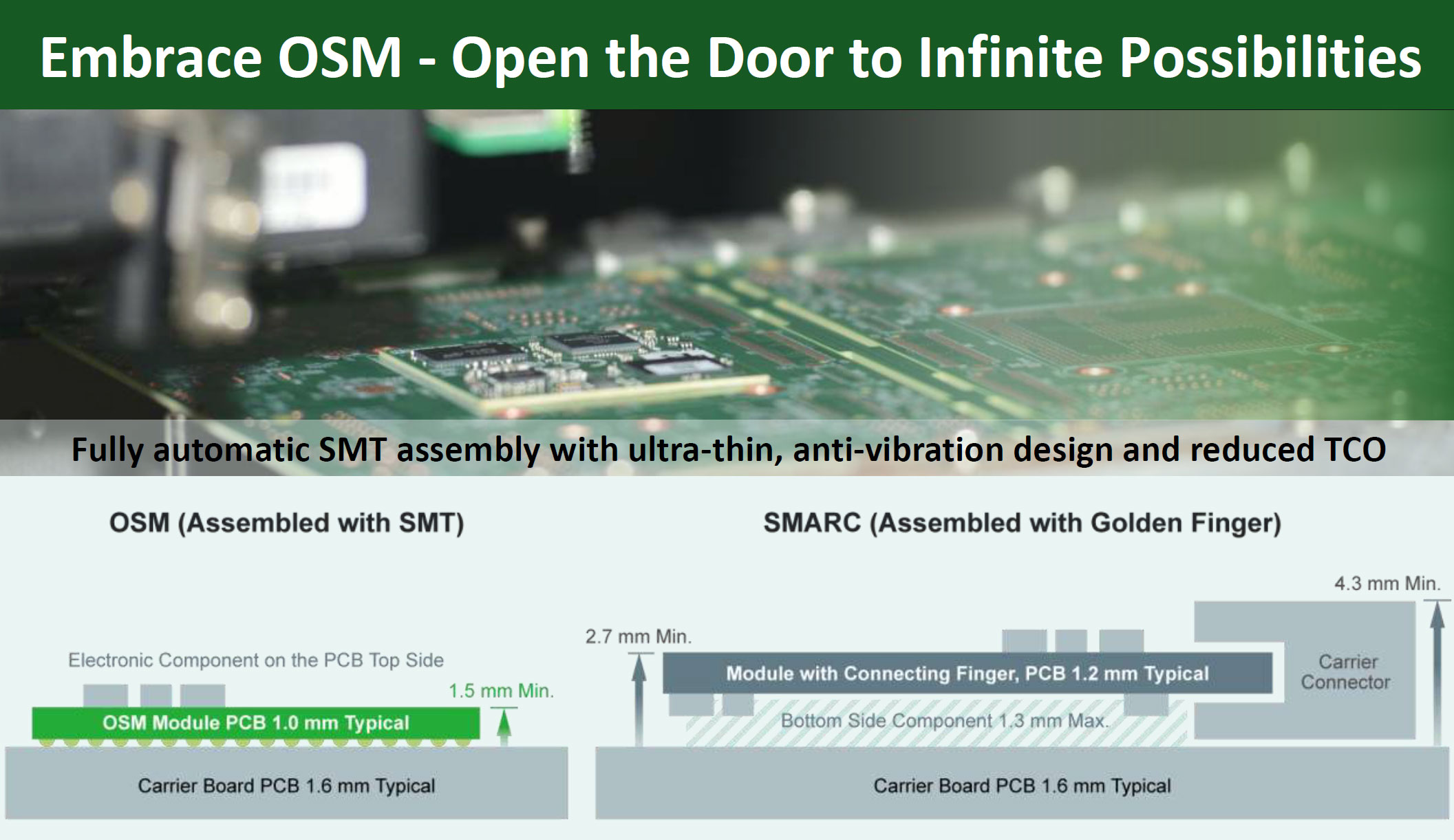

Comparison of the OSM vs. SMARC assembly situation

The OSM modules are soldered directly onto a carrier board, instead of being plugged in like an SMARC module. This allows for solutions with a significantly lower profile, which is important for applications with limited space. Machine assembly of the OSM module is much more time and cost-efficient than manually plugging in an SMARC module.

Furthermore,

- BGA provides significantly more connections in the same space.

- The short connections via solder balls enhance performance.

- The soldered modules are more robust against vibration and shock.