VacuBond® video from our american sister company Apollo

To view this YouTube video, permission is required in the Advertising section.

In close strategic and technical co-operation with the Japanese Taica-Group FORTEC Integrated GmbH developed their own optical bonding production process: VacuBond®.

Vacuum bonding (also direct dry optical bonding) allows for a zero optical defect production and provides perfect material stability without yellowing. Also modern sleek TFT displays, which do not feature a sturdy bezel, can be bonded with this production process without any problems.

Please click here for a VacuBond® video of our US sister company Apollo Displays Technology.

We solely process the Taica high-performance α-GEL® silicone (based on the silicone by Wacker Asahikasei Silicone Co., Ltd. - Wacker Chemie AG), which was developed especially for optical bonding. It features an operating temperature range of -40 to + 120°C and shows no yellowing. UV curing, which can cause stress is not necessary.

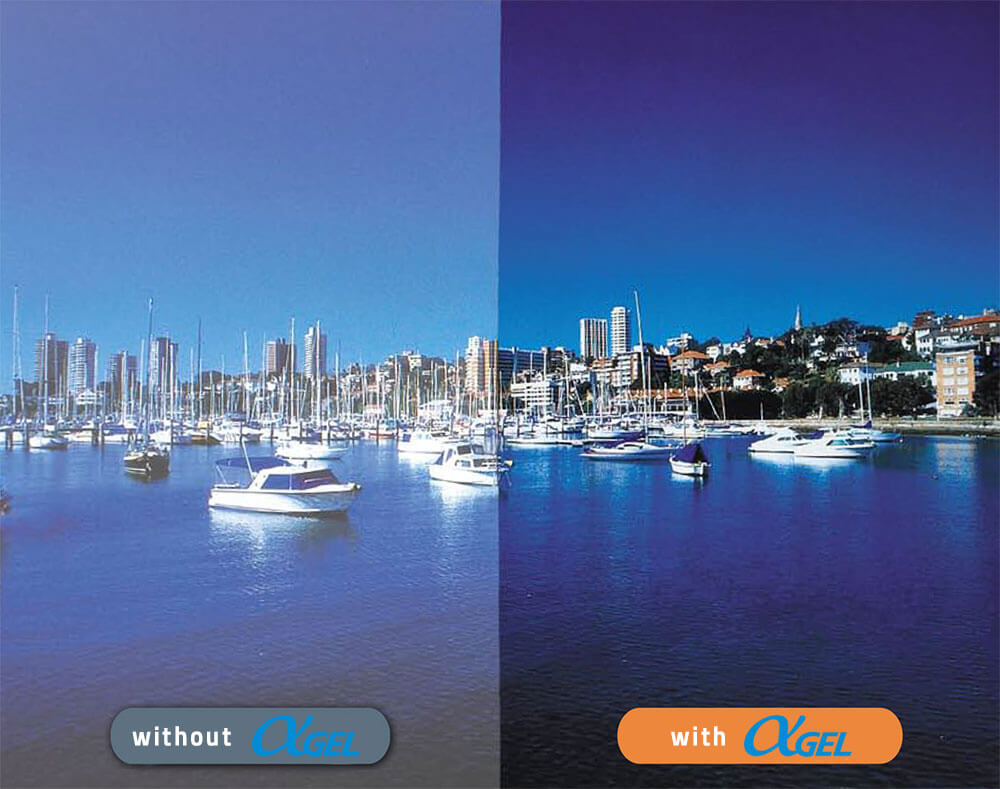

By eliminating the air gaps between the TFT display and the cover glass/touch, the light refraction is reduced and the contrast increased significantly.

Optical bonding avoids the air gap between the panes of glass - moisture cannot ingress.

Optical bonding avoids the air gap between the panes of glass - dust and dirt cannot ingress.

The danger of splintering glass is considerably reduced by the full-surface fixing / bonding with the high-adhesive α-GEL®, so that the risk of injury decreases.

Optical bonding increases the strength and resiliance of the TFT Display; the high tech α-GEL® counteracts vibration resonances and dissipates shock energy to the sides

By eliminating the isolating air gap between the panes of glass, heat can dissipate trough the front glass. This reduces the risk of heat build-up.

From autumn 2023, Taica will also offer Optogels with an integrated UV blocker, which completely shields UV radiation from 100 nm to 340 nm. This means that no UV blockers are required in the protective glass, even in outdoor applications.

We can re-bond e.g. for repair, which means no loss of expensive material.

With LOCA bonding, the liquid adhesive is cured with UV light, which can damage the TFT display or touchscreen if the dosage is too high or incorrect. This damage cannot occur with the VacuBond® process because the α-GEL® does not have to be cured.

Together with our customers a wide variety of certifications in agricultural machinery, automation, automotive, avionics, MIL, ourdoor and railway were carried out successfully.

We are offering VacuBond® as a production service for any available display, no matter if it is part of our standard product range or not.

We provide samples in any size up to 32" within a few days. In order to be even faster and more precise, we create the tools for sample productions on our own 3D printer.

The FORTEC AG has three identical VacuBond® production facilities: at FORTEC Integrated GmbH Germering, at Apollo Display Technologies in Ronkonkoma, NY / USA and FORTEC Tschechien in Pilsen in the Czech Republic. Thus we ensure a reliable supply of the rising demand and maximize our comprehensive risk management for you. At these 3 locations we work with identical machines, identical tools and of course with the identical Taica α-GEL®.

The strength of VacuBond® dry optical bonding becomes evident in the bonding of electronic paper, which, in contrast to TFT displays, has no mechanically stable structure and no bezel. The high-tech silicone αGEL® securely connects the e-paper with a protective glass or foils to a unit. The smooth surface of the e-paper is susceptible to scattered light and reflections, which is further enhanced by the air gap between the e-paper and a tape-bonded protective glass. The αGEL® fills this air gap, reduces reflections, prevents the ingress of moisture and dirt and ensures a high-contrast display of the e-paper contents. In addition to a protective glass, we also bond foils that evenly distribute the light of the front lighting. Of course, the e-paper bonding process is reversible, too.

As a medium-sized company, we specialize in order quantities of approx. 25,000 pieces / year, but also co-operate with OEMs:

To view this YouTube video, permission is required in the Advertising section.